polymer recycle plants

a stable and sustainable washing process

Gain control over your process with FerSol®

The washing process is unstable, involving a lot of handling

01

Constant supply of different plastics

It is difficult to achieve a stable process while the composition of the plastic feed is constantly changing.

02

Different types of chemistry and detergents

The vast amount of chemicals and detergents make the washing process unnecessarily complex and require a lot of handling such as ibc switches, venting of pumps and loading and unloading.

03

Inconsistent granulate quality

The many variables in the washing process result in a variable quality of the plastic granulate.

You will achieve these results with FerSol®

Reduce chemicals

FerSol® replaces traditional chemistry such as soap, lye and antifoam. Simplify the washing process.

Improve washing quality

The washing quality and the end product improve thanks to the strong oxidizing effect of FerSol®. In addition, the washing quality is more consistent because you use less different agents.

Reduce handling

Due to the reduction of chemicals and detergents by 88%, less handling is required such as tote switches, venting of pumps, loading and unloading. In addition, FerSol® is easier to use.

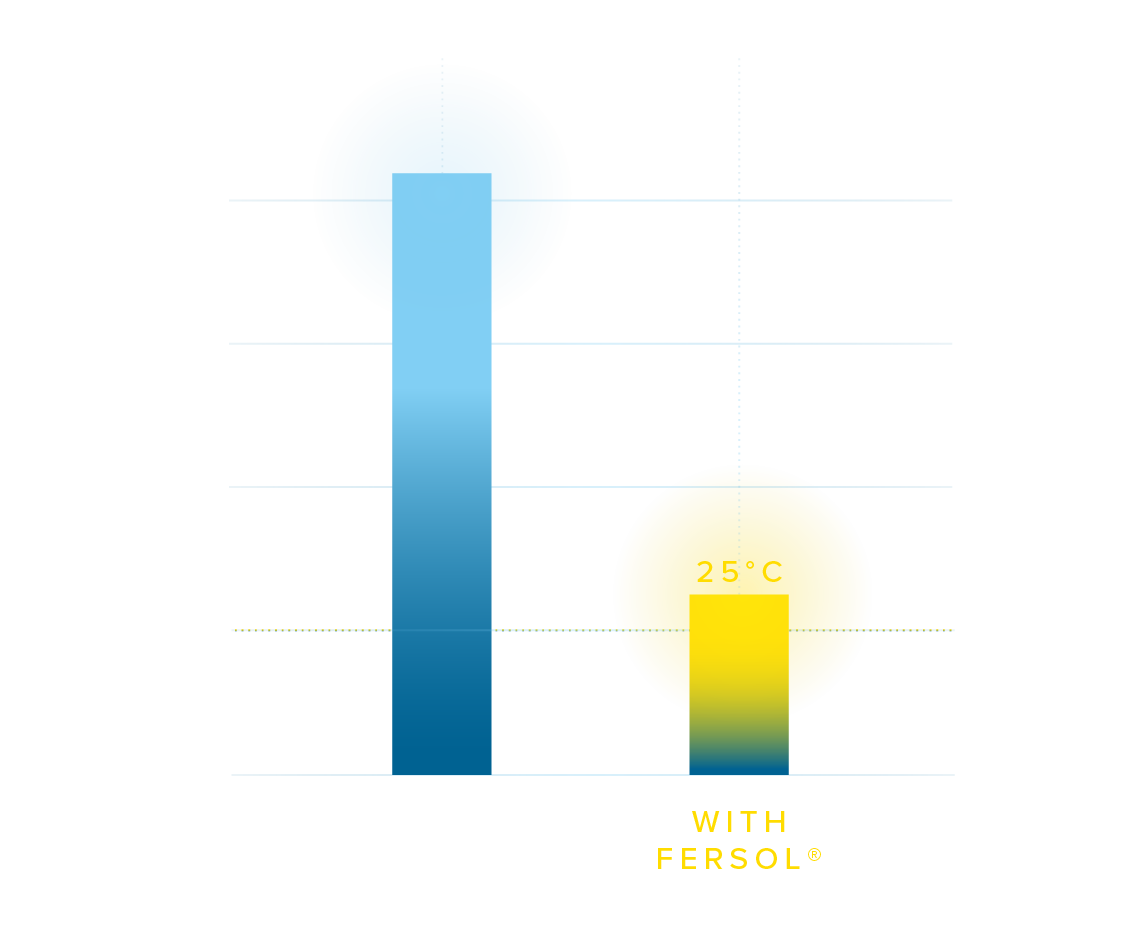

Reduce washing temperature by 70%*

The powerful purification with FerSol® allows you to reduce the washing temperature by 70%. This saves vast amounts of energy.

Raise environmental standards

Improve your ecological footprint by reusing water, reducing energy consumption, reducing transport and by replacing harmful chemicals with FerSol®, an environmentally friendly alternative.

Create better workplace

By using FerSol® you lose the unpleasant odors that are released during the washing process. This improves the workplace environment. In addition, the granulate is also free of odor.

FerSol® in practice

We achieved these results at a large Polymer Recycle Plant:

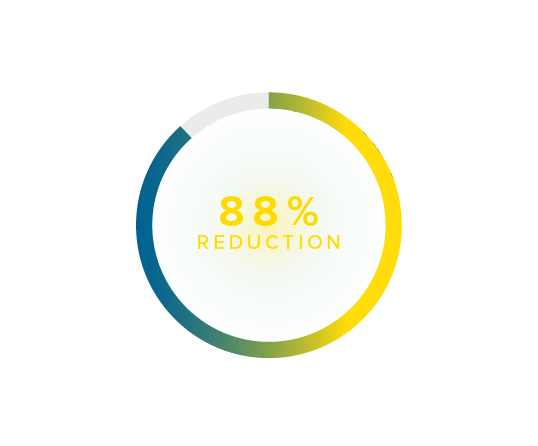

88% Reduction in chemicals and detergents

FerSol® has replaced traditional chemistry such as soap, lye and antifoam. On top of that, we achieve a reduction of 88% in the use of chemicals and detergents.

Washing temperature reduced from 85°C to 25°C

Thanks to the powerful purification of FerSol®, we have reduced the washing temperature by 70%.

Optimize water reuse

The residual water becomes so clean that we are able to reuse water in the process.

Granules free of odor

The unpleasant odors that are released in the workplace environment during the process are greatly reduced and the granulate is odorless.

“

We are absolutely thrilled with the results we are achieving with FerSol® in our washing process. We went from using 61 liters of chemicals and cleaning agents per hour to only 7.5 litres! As a result we have far less handling. At the same time we are hitting our sustainability goals, because we now use a chemical that is 100% green!

We are absolutely thrilled with the results we are achieving with FerSol® in our washing process. We went from using 61 liters of chemicals and cleaning agents per hour to only 7.5 litres! As a result we have far less handling. At the same time we are hitting our sustainability goals, because we now use a chemical that is 100% green!

Test FerSol® in your washing process

Are you curious what you can achieve in your situation with FerSol®? Experience it yourself by testing it in practice. We are happy to visit you for advice about the correct dosage, based on your washing process.

1. Invite us to your plant

Contact us and we will schedule a site visit. We will analyze your process and dicover which chemistry you use.

2. Get advice

We advise which dosage of FerSol® is required for the best result. Based on this, you can order a small amount of FerSol®.

3. Discover the power of FerSol®

Finally, you can easily test FerSol® in your process. The application of FerSol® is simple and requires no modifications to the current installation.