Prepare your company for 2027

The greenhouse horticulture sector faces a challenge. By 2027, the emissions of fertilisers and crop protection agents must be virtually zero. In addition, a purification obligation has been in force since 2018: at least 95% of the crop protection agents must be removed from the water before it may be discharged. This means that circular water provision is more relevant now than ever. How do you achieve this in a sustainable and economical way?

The rules regarding water usage in greenhouse horticulture stem from the European Water Framework Directive. This WFD obliges all EU member states to ensure a high water quality for all rivers and lakes, as well as coastal and ground waters. In addition, water must be used sustainably across the EU. This has consequences for sectors that influence the quality of surface water and groundwater, such as greenhouse horticulture. Much work has already been done in recent years to reduce water consumption and the emission of fertilisers and pesticides, but further measures need to be taken to achieve the targets.

Many greenhouse horticulture companies are already working on a circular water cycle. The possibilities for water reuse, however, have proven to be limited, particularly due to sodium levels exceeding harmful thresholds over time. In addition, some growers are reluctant to reuse drainage water when crops are affected by disease, in order to prevent it from spreading. As a result, the water often ends up being discharged. This is bad for the environment and for the company, because the discharge of wastewater is increasingly limited. That must change.

Ferrate(VI) is the strongest oxidant in the world. In addition, it reacts with dissolved substances, causing them to sink (coagulation). Furthermore it eliminates bacteria, fungi and viruses as a side effect of the strong oxidation. Ferrate(VI) is thus an all in one product. By treating water with FerSol®, the liquid form of Ferrate(VI), it water becomes so pure that it can be reused over and over. The result? A sustainable, closed water cycle.

FerSol®, the liquid application of Ferrate(VI), is the solution to meet the stringent residual water require- ments by 2027. Ferrate(VI) replaces water treatment on the basis of ozone or UV light. Moreover, it is the sustainable alternative for several hazardous chemicals, normally used in the treatment process, such as chlorine and caustic soda. In most cases, the use of FerSol® does not require any adjustment of the existing installations.

Remove biofilm from pipes: biofilm in irrigation pipes prevents the possibility to fully recirculate water. All kinds of unwanted viruses and bacteria can survive and mutate in this slimy layer of microorga- nisms. By cleaning the drip hoses with FerSol®, the biofilm is removed efficiently and sustainably.

Handle crop rotation with care: stop watering in time so that substrate slabs are as dry as possible. Discharge drained and cleaning water to the sewage system instead of the surface water.

Track down leaks: a study by Wageningen University & Research (WUR) shows that about 1.5% of the used water leaks to the ground. This percentage can be further reduced by regularly checking connections and resolving defects.

Invest in technology: a lysimeter and drain meter reveal the leaching to the subsoil or the drainage system. Soil moisture sensors reveal trends in soil moisture content. As a result, the watering and fertilisation processes can function in harmony.

Have your residual water tested by Ferr-Tech for free to see which fertilisers and pesticides it contains. Based on our analysis, we will make a proposal for safe and responsible reuse.

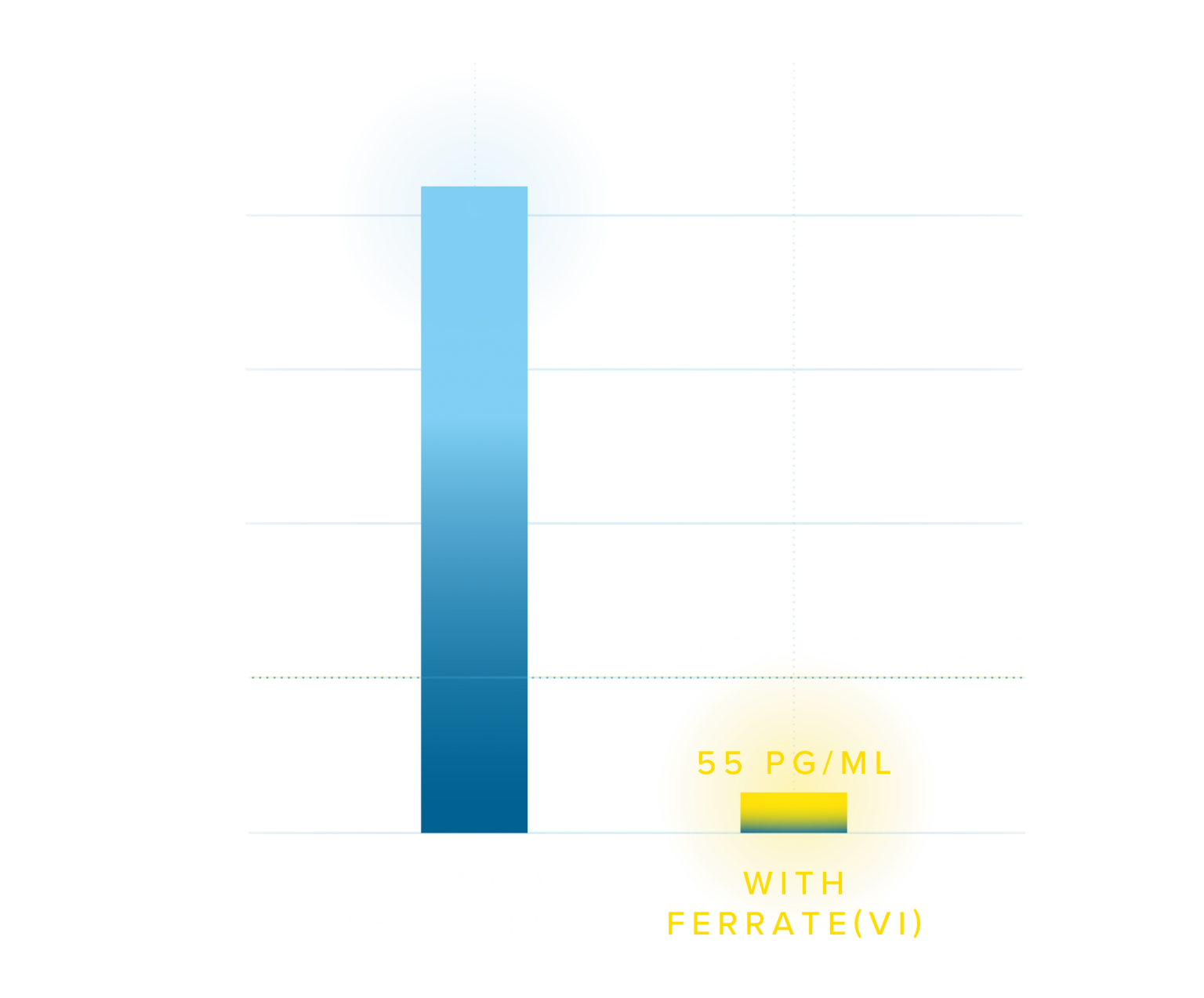

ATP reduction from 858 Pg/ml to 55 Pg/ml

” We performed ATP measurements after treating drain water with Ferrate(VI). The results of the measurements were very good. The decrease was substantial, from 858 Pg / mL to 55 Pg / mL and well below our target of 200 Pg / mL. We are now looking at what Ferrate(VI) can do for us in practice. We are investigating the possibilities of cleaning the tubes with for instance. We also want to make our water process circular with this green chemical. “

Did you find this information relevant? Download the pdf.

Ferr-tech has been named the most innovative company in NL!

Ferr-tech is named most innovative company in NL!

Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-advertisement | 1 year | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Advertisement". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.

| Cookie | Duration | Description |

|---|---|---|

| bcookie | 2 years | This cookie is set by linkedIn. The purpose of the cookie is to enable LinkedIn functionalities on the page. |

| lang | session | This cookie is used to store the language preferences of a user to serve up content in that stored language the next time user visit the website. |

| lidc | 1 day | This cookie is set by LinkedIn and used for routing. |

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | This cookie is installed by Google Analytics. The cookie is used to calculate visitor, session, campaign data and keep track of site usage for the site's analytics report. The cookies store information anonymously and assign a randomly generated number to identify unique visitors. |

| _gid | 1 day | This cookie is installed by Google Analytics. The cookie is used to store information of how visitors use a website and helps in creating an analytics report of how the wbsite is doing. The data collected including the number visitors, the source where they have come from, and the pages viisted in an anonymous form. |

Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads.

| Cookie | Duration | Description |

|---|---|---|

| bscookie | 2 years | This cookie is a browser ID cookie set by Linked share Buttons and ad tags. |

Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet.

| Cookie | Duration | Description |

|---|---|---|

| _ga_9KSNT754Q6 | 2 years | No description |

| _gat_UA-190456740-1 | 1 minute | No description |

| AnalyticsSyncHistory | 1 month | No description |

| UserMatchHistory | 1 month | Linkedin - Used to track visitors on multiple websites, in order to present relevant advertisement based on the visitor's preferences. |